Knitting

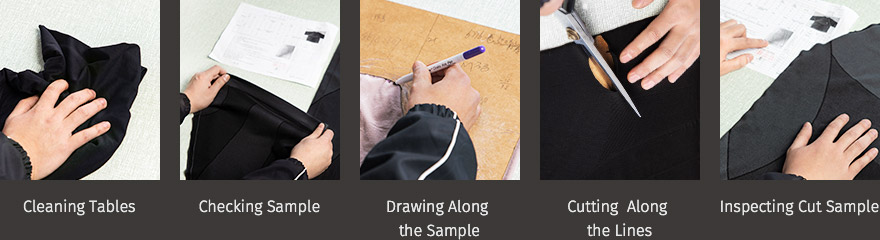

Each order will not start knitting before confirmation of the pre-production sample. Our preparation includes:

① Check and confirm if the raw materials and threading are correct;

② Carefully measure whether the technical dimensions of the products are correct;

③ Check whether the quality of the cloth is qualified.

During the knitting process, our inspector will examine the status and output quality every 2 hours.