Quality

Control Processes

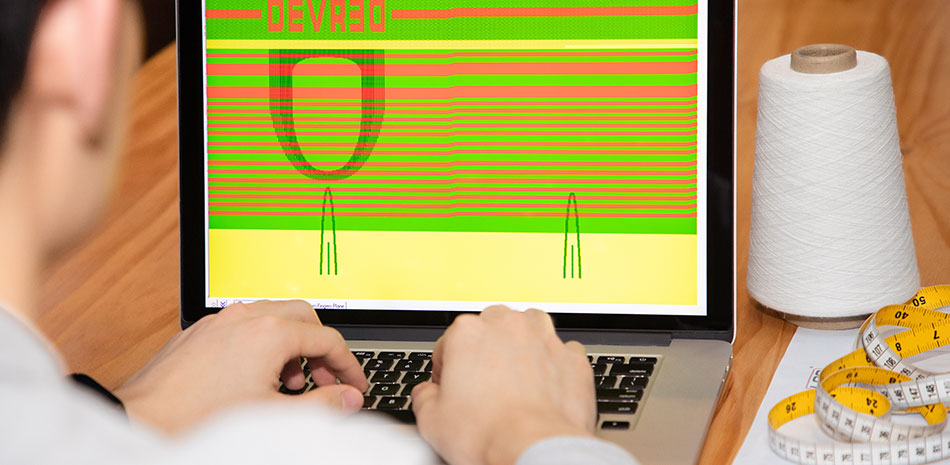

In TWINALL, we value quality in all of our seamless clothing items. We guarantee that all of our seamless activewear meet the requirements of your business. Through our knowledge of the supply chain network, we identify the best yarns and fabrics for our seamless wears. All of our inspected materials are identified and used while also checking on the machines and their performance. Years of experience have helped our quality control teams monitor all deliveries with much success.

Learm How We Control Quality